技术领域

本发明是纯水生产过程中一级反渗透系统提高制水得水率的装置。

背景技术

在纯化水的生产过程中一般都使用反渗透装置来去除水中前过滤装置未过滤掉的机械杂质、有机物和99%以上的离子,来获得纯化水。在这操作过程中,水必须通过加压后才能通过反渗透膜,加压后的水透过了反渗透膜使水得到净化,经过净化的水被送入到下一流程继续净化或进行使用;而含有机械杂质、有机物和离子的浓水在膜的另一侧随着水流排出一级反渗透装置。其净化水与进水之比为70%左右,30%的浓水经过减压以后就作为废水排入到城市污水管网中。本发明就是利用一级反渗透装置浓水侧的余压把30%的浓水经过本装置进行净化,净化后的水送入到一级反渗透装置前的储罐,作为一级反渗透的部分进水,减少前级装置的水处理量。减少废水的排放,提高能源利用率,减少制水过程中自来水的消耗。

发明内容

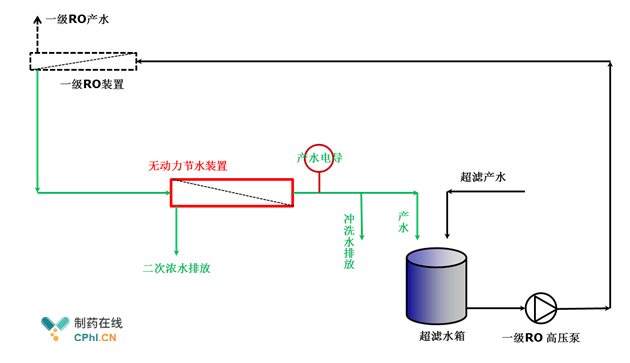

流程:

流程描述:

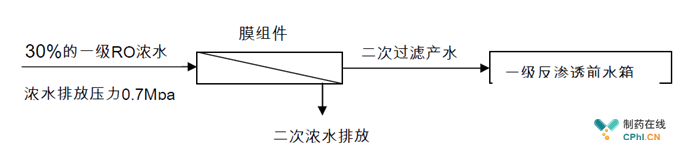

加压后的水透过了一级反渗透膜,获得了70%的净化水,同时还有0.7Mpa压力的30%的浓水通过减压以后必须排出一级反渗透装置。本装置利用这一余压把这些水重新压入从正常制水系统报废的旧膜中而获得二次过滤产水,二次产水送入一级反渗透前水箱。从而使一级反渗透装置的得水率从70%提高到88%以上。

一级反渗透膜进水水质提高:

一般自来水的电导率为300~400µs,经过前级处理以后在进入一级反渗透前水箱时其电导基本不变。当一级反渗透浓水经过本装置以后产出的二次产水其电导为45~60µs,这个二次产水与 300~400µs的水进行混合以后,此时一级反渗透前水箱中水的电导将下降到200µs左右。大大改善了一级反渗透膜的进水水质,由于一级反渗透进水电导的下降,使得一级反渗透出水的水质改善,出水电导下降3~4µs。进水水质的改善又使得一级反渗透膜的使用寿命获得延长。

报废反渗透膜的再次利用:

一级反渗透膜或二级反渗透膜在经过一定水流量的过滤以后,其产水电导上升、流量下降、进水侧与产水侧的膜间压差增大,此时膜必须进行更换才能保持系统的正常生产,报废膜作为垃圾进行处理。通常一级膜的电导大于 20µs以后就需要更换,本装置把所有的膜壳进行并联组合,把报废的膜装入每个膜壳中,在每个膜壳前、后加装阀门,通过膜壳前后的阀门的开闭,来调节膜壳投入运行的数量,从而调节二次产水的产量。

余压的充分使用

高压泵把水加压以后使水透过了一级反渗透膜而获得净化的水,但在浓水侧还有0.7Mpa的压力,在浓水排入下水道时必须减压排放。本装置在保持一级反渗透装置膜间压差不变的情况下,通过开启本装置膜壳数量的多少来利用浓水排放的余压来过滤浓水,所以本装置无需新增动力,高压泵能量得到了充分的利用。

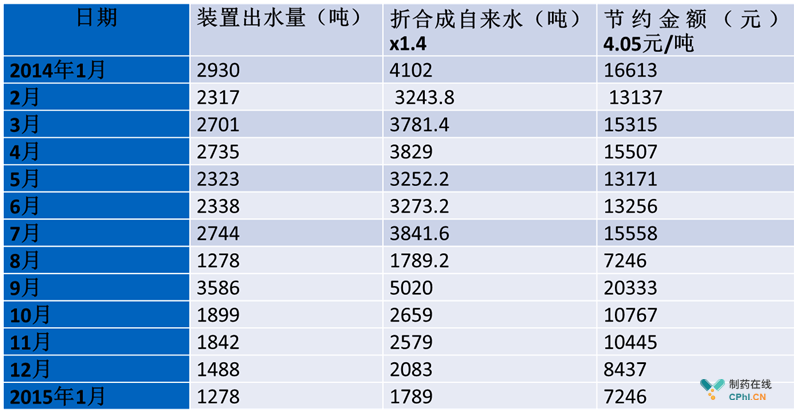

实际产生的成果

费森尤斯卡比华瑞制药有限公司在2013年5月份在一个22立方米/Hr的纯水站安装了本装置,该装置已经连续运行到至今,近5年时间。每小时一级反渗透装置排放15~16吨废水。在2013年以后这些排放废水就进入了这个节水装置,2014年这个装置就节约自来水4万吨(公司全年用水50吨),随着纯水量每年的增加,节水量也在不断扩大。该纯水站制水系统少进自来水,纯水站节约电能5%,污水每月少排5吨以上。

2014年节水统计

获得国家发明专利

Water Saving Device of First Stage RO Water

Technical Domain

This invention is a device help improve yield of purified water in the first stage RO process.

Background

By using extra pressure on side of high solute concentration water in the first RO process, this water saving device purifies high solute concentration water, 30% of original feed water. After purification, the solvent will be sent to a tank before RO process as part of feed water for RO process, which helps decreasing water treatment amount, reducing discharge amount of waste water, improving energy utilization rate as well as decreasing consumption of tap water.

Details of invention

Operational process:

Quality improvement of feed water in the 1st RO process:

In general, conductivity of tap water is about 300~400µs and conductivity keeps the same after treatment process before RO. However, conductivity of solvent through this device is reduced to 45~60µs. When tap water mixed with the treated solvent, whose conductivity is reduced to around 200µs, enormously improve quality of feed water for RO process. Thus, quality of water treated after RO process also gets great improvement, whose conductivity will decline 3~4µs compared with water without treated by the invented device. Moreover, quality improvement of feed water also extends service life of membrane in RO process.

Reuse of scrapped membrane:

After filtering certain amount of water, efficiency of membrane used in RO process will decline, causing problems such as increase of treated water conductivity, decrease of water flow and increase of differential pressure on two sides of membrane. To keep normal operation of water treatment system, membrane must be changed. Used membrane usually will be scrapped directly. In general, membrane needs be changed if its conductivity exceeds 20µs. This water saving device is composed of parallel membrane shells with scrapped membrane inside and valves at both ends. Via opening or closing valves to control quantity of working membrane and then control yield amount of treated water.

Fully use of extra pressure:

High pressure pump push water through membrane in RO process and then get purified water. On the side of high solute concentration water area, there is 0.7Mpa extra pressure, usually will be reduced before discharge high solute concentration water. This water saving device use the extra pressure to filter high solute concentration water, which is supposed to be discharged directly before adding water saving device, so there is no need of new power and efficiency of high pressure pump has been fully used.

专家简介:叶勋,高级工程师,费森尤斯卡比华瑞制药有限公司技术服务部副经理,中国医药设备工程协会专家委员会委员,20多年以来致力于研究制药用水的生产与输送,拥有多项发明专利。

合作咨询

![]() 肖女士

肖女士

![]() 021-33392297

021-33392297

![]() Kelly.Xiao@imsinoexpo.com

Kelly.Xiao@imsinoexpo.com

2006-2025 上海博华国际展览有限公司版权所有(保留一切权利)

沪ICP备05034851号-57

2006-2025 上海博华国际展览有限公司版权所有(保留一切权利)

沪ICP备05034851号-57